Manufacturing is crucial to the economic growth of a wide range of markets. For industries to run efficiently and grow, they need a variety of machinery. For example, industrial combustion systems are crucial for the manufacturing industry. Similarly, a bucket elevator is essential for the power, mining, and cement industries.

A bucket elevator is a type of equipment that transports materials in huge quantities. It’s a beneficial device in many different settings and industries. Keep reading to learn more about bucket elevators, their uses, and their different types.

Understanding Bucket Elevators

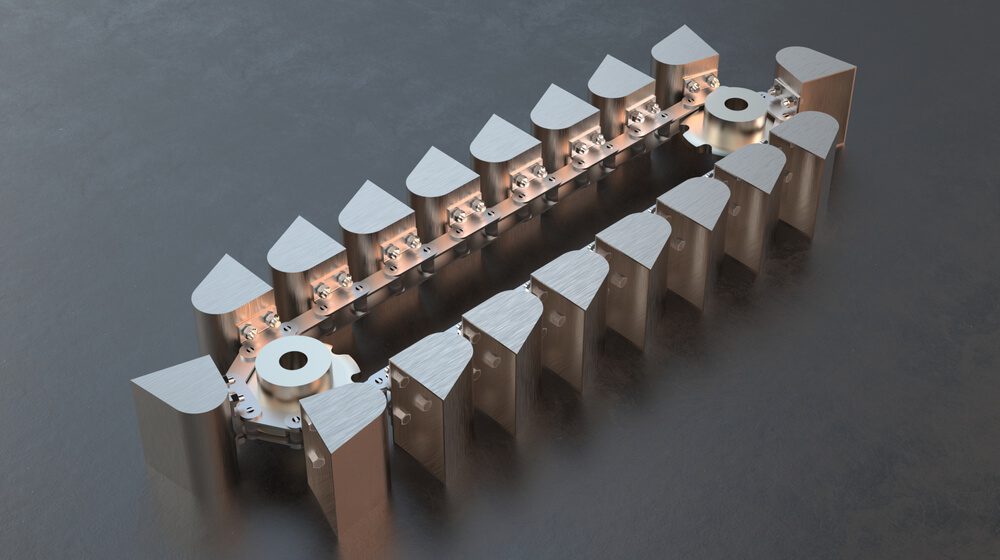

Producers need to understand how their industrial process equipment works. Doing so lets them run a successful business. So, here is a breakdown of bucket elevators and how they work. Think of a bucket elevator as a conveyor belt with buckets fastened.

Producers need to understand how their industrial process equipment works. Doing so lets them run a successful business. So, here is a breakdown of bucket elevators and how they work. Think of a bucket elevator as a conveyor belt with buckets fastened.

The elevator moves products in bulk using reciprocating buckets. A bucket elevator can move material horizontally and vertically. But, it is best suited for vertical movement.

The buckets swivel to ensure they stay upright to keep the contents from spilling. The buckets usually have scooped edges to let them pick things through dragging.

A vertical bucket elevator ferries materials upwards and empties them at the top. Once empty, the bucket goes back to pick more materials. The loading and depositing of materials are quick and automatic.

Bucket elevators often have shields to protect people. Shielding is particularly crucial if the buckets are on a chain rather than a belt. A chain can get a hold of clothing, hair, arms, and legs, causing severe damage to the victim. You can find bucket elevators in action in sugar conveyors and grain elevators.

Types of Bucket Elevators

There are different types of bucket elevators. The choice of a bucket elevator will largely depend on what and how much you want to move. The type of conveyor system you have will also influence the decision. The types of bucket elevators include:

Centrifugal Bucket Elevator

A centrifugal bucket elevator specifically transports free-flowing products. It uses centrifugal force to transport the materials. The buckets are of malleable iron, steel, or synthetic material. They then get mounted onto a belt or chain.

The buckets get attached to the chain or belt at particular intervals. A digging boot and material flow help with the process of loading the buckets. After the buckets get filled, they dump the material at the discharge point through centrifugal force. The discharge point is usually at the top of the turn of the chain to optimize the centrifugal force.

The buckets on a centrifugal bucket elevator stay within a metal enclosing. Doing so helps keep the material from getting out at any point other than the discharge point. Any leftover material in the bucket will go back down, and the process will start again.

A centrifugal bucket elevator can use both high and low speeds. Those that use the highest setting usually transport lighter materials. The centrifugal bucket elevator is great for moving products like grain, minerals, and sugar.

Continuous Bucket Elevator

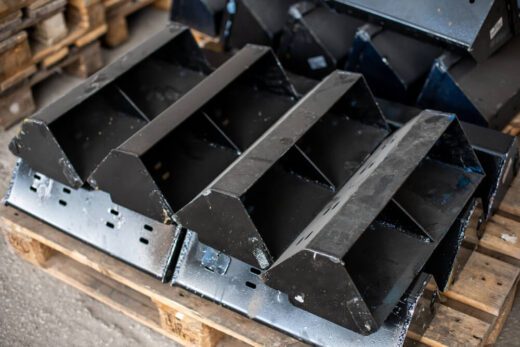

You can attach a bucket on one or two chains in a continuous bucket elevator. For the latter, there’s a bucket on each side. The buckets get fastened on a continuous loop and move at low speeds. Continuous mounting means there is no gap between the buckets.

It keeps the materials from spilling. A continuous bucket elevator moves fragile or light products. So, the low speeds ensure the safety of the contents. The buckets get filled one by one by the inlet, and there is no digging involved.

The buckets then use gravity to dump the materials. Continuous bucket elevators usually have large buckets to make up for the slowness. They are advantageous in the plastic and mining industries.

Finding the best equipment can be challenging, given the different bucket elevators available. But, all you have to do is determine what you need it for and the conveyor you have.

Uses of Bucket Elevators

Bucket elevators can help move large amounts of materials. Thus, many industries use this technology, including:

Bucket elevators can help move large amounts of materials. Thus, many industries use this technology, including:

- Cement, power, and biomass industries

- Minerals and mining industries

- Glass, pulp, and paper industries

- Fertilizer and biomass industries

For your industrial elevator equipment to work well, you must properly maintain it. Maintenance includes repairing and replacing parts necessary.

Final Thoughts

Moving large amounts of material can seem daunting. A bucket elevator comes in to solve that problem. It ferries an enormous amount of product quickly, making it popular among many industries. Hopefully, you now have a better understanding of bucket elevators.

For further questions, contact Lindberg Process Equipment today.