Protect Your Boiler Rooms By Understanding CO Safety

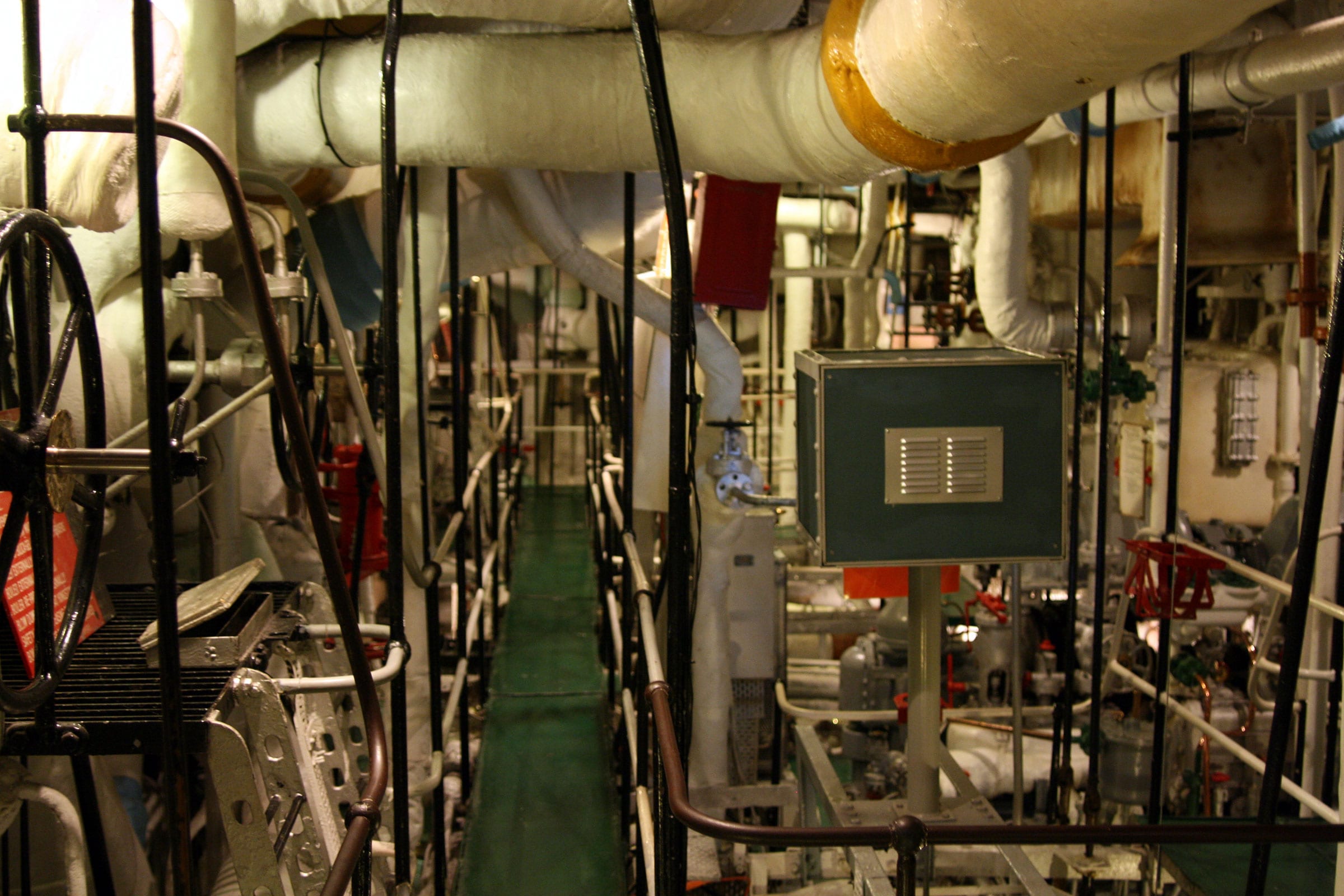

Boiler rooms have many safety standards that must be kept up with to remain compliant with a wide variety of codes. These standards are in place to ensure that the staff and the operation itself stay protected.

These compliance factors cover a lot of minutiae, many of which we simply do not have the time to discuss today. However, here’s an overview of a gas-fired boiler code compliance brief if you would like to learn more.

Now, we’re going to talk about a very specific area of concern for boiler rooms. Unfortunately, this issue occurs far too much. So, what are we here to talk about today? We’re discussing the generation of carbon monoxide (CO). While CO doesn’t cause massive property damage or leave behind physical traces of destruction — it can spell disaster for the health of employees if it’s poorly managed.

Some Quick CO Info

Before we dive too deep into boiler room safety, let’s talk about carbon monoxide for a second. There’s a reason why they call this gas the “silent killer.”

- Carbon monoxide is colorless, tasteless, and odorless

- It’s a non-irritating gas

- When fuel doesn’t burn completely, it generates CO

- Carbon monoxide poisoning can cause a wide variety of symptoms such as dizziness, headaches, upset stomach, vomiting, chest pain, weakness, and confusion

- Too much CO can cause one to pass out or even die

- Small children, infants, and people with certain chronic diseases are at the highest risk of CO sickness

- More than 400 people die each year in the United States from unintentional CO poisoning

Some of this information you may already know. However, it’s important to note how impossible CO is to detect without proper tools and instrumentation. The scary part is how many times we hear stories about boiler industry employees bragging that they can “eyeball a flame” or detect CO on their own. Luckily, education practices and strict regulations have limited the number of people that believe myths like how blue flames don’t contain CO.

Even so, there are plenty of boiler industry employees that will benefit from more information regarding CO emissions.

Why Does CO Occur in Boiler Rooms?

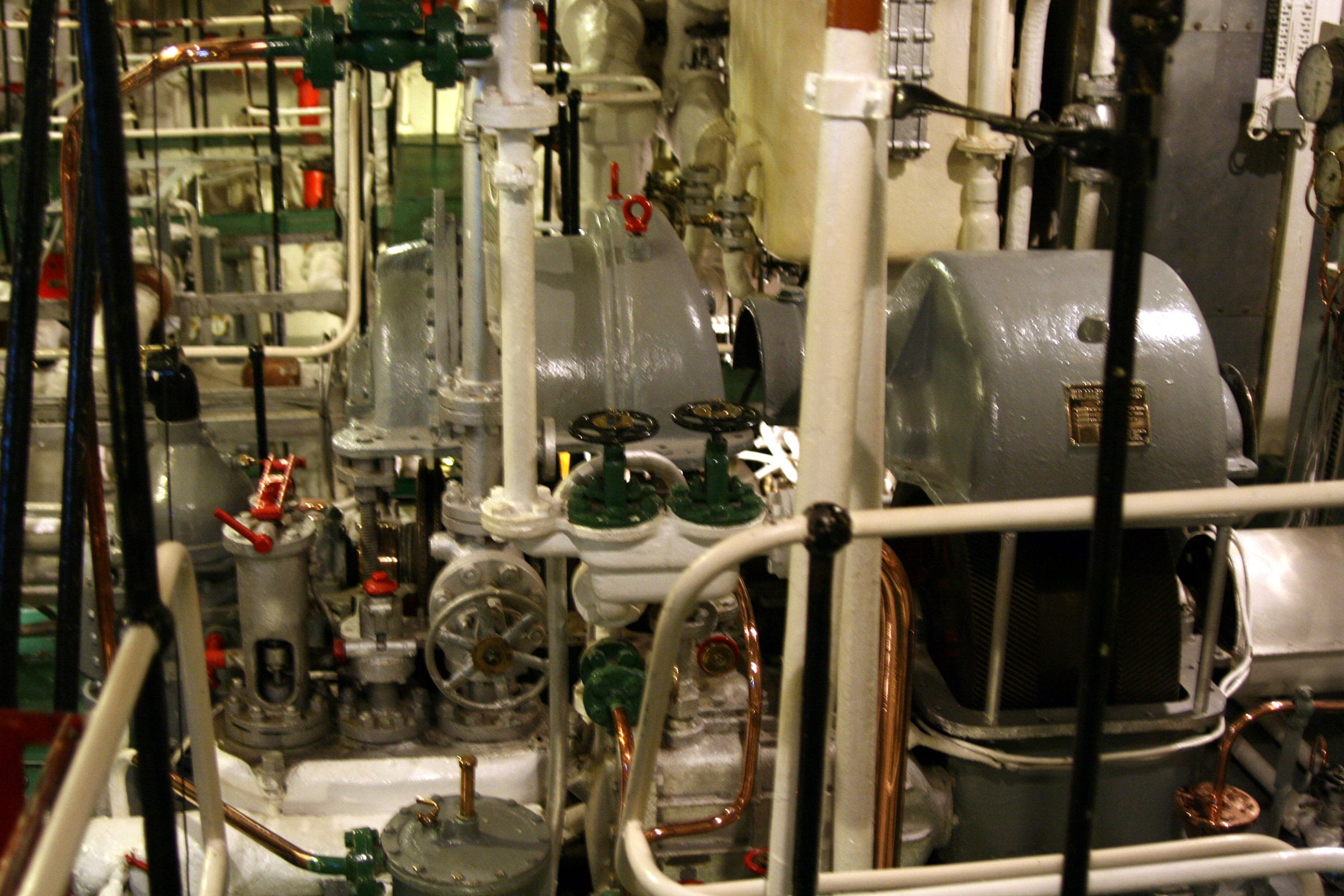

The combustion process fuels all boiler rooms. So, it’s important to understand why this process generates CO. There are technically two ways that CO is created.

- The combustion air and fuel that is burned doesn’t mix properly, causing CO.

- Fuel doesn’t burn all the way because there isn’t enough combustion air.

Scenario two is what typically happens in a boiler room, so we’re going to focus solely on how this scenario can occur.

Combustion Air Opening Issues

If the air openings weren’t installed properly or designed correctly, it could decrease the amount of combustion air needed for proper operation. Also, if these air openings were modified or a worker interfered with them, the same issue can occur.

The Fuel Input is Too High

Burner combustion control systems are there to control the air/fuel ratio. If the fuel input is too high and is subsequently outside of the system’s intended range, it won’t be adequately burned off. CO could then be dangerously generated.

How To Protect Your Boiler Room From CO Issues

So, now you know what causes the generation of CO and how it can happen in a boiler room. Now let’s go over some scenarios that have caused these two problems and how to fix them.

The Winter Issue

When it gets too cold outside, boiler rooms can get pretty chilly also. Much of this cold air comes from air intake louvers, and unfortunately, there have been cases where these have been blocked by boards or sheets to keep the cold out.

Blocking air intake is a recipe for disaster. If the boiler operator finds it too cold, either install an air heater or relocate the air intake.

Not Enough Air

Sometimes, negative pressure can occur in a boiler room due to new additions that add exhaust capacity. This makeup airflow needs consideration to keep the airflow balance in check.

If not, there won’t be enough makeup airflow to keep up with the exhaust out of the plant properly. So, keep in mind any added exhaust capacity necessary after process additions.

Wrong Gas Orifice

Unfortunately, this issue has happened far too often. Many hot water boilers have both natural gas orifices and propane orifices included in the auxiliary parts package. With that in mind, installation contractors need to be especially diligent in ensuring they use the correct orifice to prevent too much fuel from being fed into the boiler.

If someone makes this mistake, lethal levels of CO can enter a building or home. Obviously, this is tragic for anyone involved and can easily be avoided with care and attention to detail.

Failing to Use CO Analyzer

Another preventable oversight is failing to use the tools and equipment that ensure CO safety. Utilizing CO analyzers to ensure that there aren’t any issues in areas such as the flue gas startup is an essential step in preventing tragic incidences.

It’s Your Responsibility

The truth is, industrial boiler room CO safety isn’t nearly as regulated as it should be. Keeping your staff and boiler room operators safe takes attention to detail, care, and the right equipment to detect issues from the start.

Boiler room engineering services can solve any potential issues you may have before they begin. These engineering services are especially helpful when undergoing changes that could affect the way CO generation occurs. If you have any questions related to boiler room processes or equipment, contact us today. We’d love to help.