There are many variables to consider before successfully installing expansion joints in your pipe system. The most critical aspect to consider is the direction of media flow and the best way to absorb the movements. Once you have the necessary information, it is pretty straightforward to determine the most suitable type of expansion joint to incorporate.

Expansion joints are an essential part of any combustion piping or ducting system. The correct choice and optimal installation of expansion joints during pipe or duct installations ensures reliability and safe operations. An expansion joint mitigates the impact of thermal expansion and contraction, movement caused by vibrations, and seismic activity.

What Is an Expansion Joint?

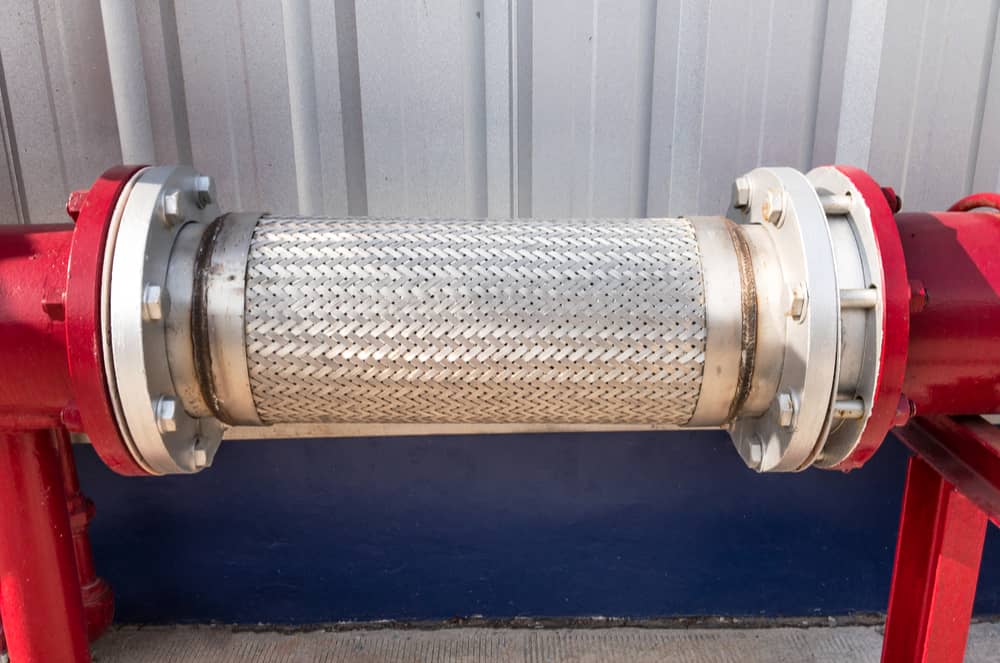

An expansion joint is a mechanism often installed between sections of piping systems, bridges, buildings, railway tracks, and other structures to safely absorb vibrations, seismic activity, pressure or temperature-induced expansion or contraction. Expansion joints offer one of the best mechanisms to deflect expansion stress.

Expansion joints are often used in tight, enclosed areas. They act as shock absorbers, which allow media to move freely within the pipe. Expansion joints are manufactured from a wide variety of materials, including stainless steel, polytetrafluoroethylene (PTFE), and rubber. They are particularly essential where industrial processesexperience significant temperature changes, posing potential damage to the piping or building structure.

How to Select the Right Expansion Joint for Your Piping Needs?

The right expansion jointshould meet the chemical, pressure and temperature requirements of your piping system. The type of expansion joint you select should be determined by a variety of factors. These include; the purpose of the expansion joint, the type of materials being conveyed, chemical resistance, and the pressure & temperature.

Selecting the most appropriate expansion joint for your application will offer a more economical and longer-lasting solution. Let’s take a closer look at the factors to consider when choosing an expansion joint for your application.

#1. Location of the Expansion Joint

Pre-planning your piping system will allow you to determine the most ideal placement of your expansion joints. Proper placement of expansion joints allows movement allowance, easy accessibility, and adequate cooling for your piping system. Moreover, you will be able to determine the idyllic type of expansion joints to install.

#2. Media Being Conveyed

Most aspects of design and build for the right expansion joint are determined by the liquid or gas being conveyed through the joint. Some expansion joints are lined with insulation bolsters or flow liners to protect the joints from abrasive media. It would be wise to consider these types of expansion joints if your piping system is meant to convey dirty or abrasive elements.

Materials that have turbulent flow could cause “flutter” in your expansion joints if they are made up of the wrong material, which dramatically shortens their lifespan. It is, therefore, critical to make sure your expansion joint is made of materials that can support the media you intend to convey.

#3. Temperature

Your piping system’s operating temperatureis among the most essential factors to consider when selecting the right expansion joint. Your application may require materials to be conveyed at high or low temperatures for optimal results. The temperature requirements will determine the right materials, frame design, and components to use in your expansion joints.

#4. Pressure

Piping systems have different pressure requirements depending on the materials being conveyed and their purpose. The pressure requirements determine the expansion joint’s fabric material and the reinforcements needed. For high pressure piping systems, reinforced rubber expansion joints and metal bellows are recommended. Lower pressure systems could use reinforced fiberglass fabric. If not addressed, pressure fluctuations and pulsations could significantly shorten the life of your expansion joints.

#5. Installation

It is essential to consider any transportation or installation limitations that are in close proximity to the expansion joint. While most expansion joints are often shipped fully assembled and ready for installation, larger sizes may need to be shipped in sections or even assembled on-site.

Depending on the duct flange arrangement and accessibility, it is always essential to allow enough room for proper installation and future maintenance activities.

#6. Movements

Some types of expansion joints are designed to mitigate the impact of extreme vibration or movements on your piping system during operation. To ensure your expansion joints enjoy a long life, it is essential that all the movements expected in the environment are taken into consideration when choosing the type of expansion joints being installed.

The Best Expansion Joints for Different Piping Needs

The Best Expansion Joints for Different Piping Needs

1. Rubber Expansion Joints

High temperature and pressure requirements often call for rubber expansion joints. This is particularly because of their inherent flexibility, which makes them ideal for a variety of applications, including sound and thermal absorption.

Rubber expansion joints are also known for their durability and ability to withstand harsh conditions. Consequently, they are commonly used in chemical processing, pulp, and paper, water waste, mining, and pumping applications. Rubber expansion joints, such as bellows expansion joints, feature flexible elements that enable your piping system to absorb angular, lateral, axial, and universal movements.

Rubber expansion joints are typically fabricated using natural or synthetic elastomers, including EPDM, Chlorobutyl, Neoprene, and Nitrile. These materials are combined with metal or wire reinforcement, polyester aramid fiber, nylon, or PTFE. Most hinged expansion joints are made of rubber and feature a spring system. Most rubber expansion joints require supporting structures for maximum efficiency.

The different rubber expansion joints include;

- Offset

- Filled Arch

- Concentric/Eccentric Reducer

- Sleeve Type

- Spool Type

- Wide Arch

- Bellows Expansion Joint

- Spherical

2. Fabric Expansion Joints

Like rubber expansion joints, fabric expansion jointsare flexible connections installed in piping systems to compensate for misalignment, vibration and thermal expansion. Fabric expansion joints combine different materials to resolve chemical, thermal, and mechanical resistance in their different applications. They are often installed in incineration, cement, FGD, power plants, metal fabrication, and food processing applications.

There are two main types of fabric expansion joints: single-layer expansion joints and multi-layer expansion joints. Single-layer expansion joints offer pressure and chemical resistance against aggressive elements. On the other hand, multi-layer expansion joints offer the utmost support for extreme heat, pressure and chemical aggressiveness in piping systems.

Some of the product types that offer fabric expansion joints include:

- FL Series Fluoroplastic

- FC Series Fluoroplastic

- M Series

3. Metal Expansion Joints

Metal expansion joints, also known as metal bellows are elastic mechanisms that allow compression and expansion by extended or applied pressure in a vacuum. This makes them ideal for thermal and vibration absorption in piping systems with high temperatures and vibration levels. Some of the types of metal expansion joints available include:

- Pump connectors

- Duct type

- Expansion Compensators

- Hinged & Gimbal

- Universal

- Externally Pressurized

- Ring Controlled

4. HRSG Expansion Joint

Heat recovery expansion joints are flexible piping systems that recover waste heat energy from hot gasses or fluids and convert it into steam. These expansion joints are often used in manufacturing industries, where heat is important in value addition and processing. HRSG expansion joints can withstand temperatures in excess of 2500*F.

5. FCCU Expansion Joint

FCCU expansion joint assemblies typically feature an external insulation (hot wall) or internal insulation (cold wall). The cold wall of an FCCU expansion joint is designed for fluid catalytic cracking, while the hot wall is designed to withstand high pressure and temperatures.

The Right Solution

Choosing the most flexible specialty products presents the best results when choosing the right design and material for your expansion joint design. Having had decades of practice selecting and installing expansion joints for customers across the divide, our engineers offer the best opportunity for you to select and install the right expansion joint for your piping system. We not only take pride in the quality of products we sell, but also in the exceptional customer attention we pay to resolve difficult situations. Get in touch with us today and make a stride towards professionally designing and installation of your next expansion joint.