If you work in power generation, you’ve likely heard reference to desuperheaters. Desuperheaters are secondary heat exchanger devices allowing fast and efficient heat transfers from external sources to domestic hot water tanks. There are many benefits to using desuperheaters, and they offer distinctive features compared to traditional heat mechanisms.

Use this guide to learn more about the powerful desuperheater—and how you can implement this sophisticated technology in your business and beyond. Alternatively, contact desuperheater experts to learn more about the desuperheater’s system, design, and implementation.

How Desuperheaters Work

Desuperheaters cull heat from the earth or inside a home or building and transfer that heat to hot water tanks. They are most often used in conjunction with refrigeration and air conditioning systems in industrial contexts because they offer more power and efficiency than traditional secondary heat exchange systems. Additionally, they establish intimate contact between steam and cooling water, maximizing overall efficiency.

Desuperheaters cull heat from the earth or inside a home or building and transfer that heat to hot water tanks. They are most often used in conjunction with refrigeration and air conditioning systems in industrial contexts because they offer more power and efficiency than traditional secondary heat exchange systems. Additionally, they establish intimate contact between steam and cooling water, maximizing overall efficiency.

Most heaters work by returning superheat temperature to a preferable temperature within 3 degrees of saturation. The machine works by injecting a specific amount of cool water into a steam flow, which then transports or reduces heat. For this reason, they are used to prevent shutdowns and avoid industrial complications related to overheating.

Desuperheaters vs. Attemporators

Attemporators traditionally work to control steam temperature. They are typically most common in situations involving overheated boiler steam or industrial burners. Many industries leverage attemperators to minimize overheating between superheater zones in multi-zone superheater steam boilers or re-heater zones to adjust for reheater outlet temperature.

Although attemperation technology has existed since the early 20th century, desuperheaters are relatively modern in comparison. Desuperheaters are also typically found in steam lines at a distance from the boiler or outlet pipe. Industry professionals use desuperheaters when there is a downstream purpose for saturated steam.

As a result, desuperheaters promote sustainability and maximize resources without creating waste. Desuperheated steam also hovers between five and ten degrees Fahrenheit above the saturation point. This temperature range allows the controller to effectively detect steam temperature.

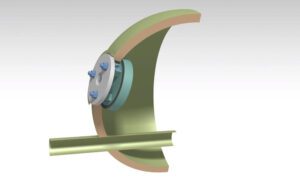

Desuperheater Design and Installation

Desuperheaters are typically double-walled tubes with vents. Desuperheaters often work with freon, ammonia, or other refrigeration fluid, so the vents are serrated inside and outside to prevent the cross-contamination of water with the liquid. Each tube inside the machine has another line built in to allow for heat exchange.

The heaters are often installed before oil separation. They are placed before the condenser to allow the refrigerant to travel through the tubes and into the condenser. The machine also generates and stores hot water in an exterior, insulated tank to allow for immediate use.

Benefits of Desuperheaters

There are many unique benefits to using desuperheaters in various industries. Consider the following before investing.

Maximize Boiler Performance

Desuperheaters are particularly useful because they can help maximize boiler performance and improve your internal operations. They help preserve the longevity of expensive machinery by preventing common overheating issues down the line.

State-of-the-Art Technology

Desuperheaters leverage the latest technological developments to create the most efficient heat-exchange system possible. To that end, they maximize efficacy and often provide more functionality over the long term.

Free Water Heating

Desuperheaters pull heat from household surfaces into the hot water tank. This process is entirely free and capitalizes on existing resources. You only have to consider the cost of operating the machine’s pump to move the water, which is negligible.

Sustainability

Because these heaters use pre-existing heat, they are more sustainable and resource-efficient than traditional heat exchange methods.

Learn More About Desuperheaters Today

Understanding how desuperheaters work is a massive advantage to most power-related industries and professionals. These powerful machines have revolutionized the power, industrial, and mining industries with unparalleled efficiency and multi-purpose use. They promise to continue evolving to meet the needs of sophisticated, modern sectors.

If you are interested in learning more about desuperheaters and how you can leverage them in your field or business, consider reaching out to us for more information. As experts with decades of experience, we can provide you with the knowledge and expertise you need to take your work to the next level. Contact us today to speak with a qualified representative about our state-of-the-art heater systems.