In the dynamic realm of energy and combustion systems, the challenge of effective thermal management takes center stage. As our demand for energy-efficient and high-performance systems continues to grow, so does the need for cutting-edge solutions to tackle the heat generated by these intricate processes. In this article, we’ll explore the current state of heat processing products and dive into the transformative technologies that are shaping the future of thermal management in the energy and combustion systems industry.

The Vital Role of Thermal Management in energy and combustion systems

Thermal management stands as a linchpin in the intricate machinery of energy and combustion systems, serving as a critical force in the optimization of both efficiency and safety. In this multifaceted industry, where the controlled release and utilization of energy are paramount, effective thermal management is not merely a feature but a foundational necessity. Whether within the towering structures of power plants or the robust engines propelling vehicles forward, the strategic dissipation of heat is an indispensable factor that dictates the performance, reliability, and longevity of vital components.

Within the sprawling facilities of power plants, where the transformation of raw energy sources into electricity takes place, the efficient management of heat is non-negotiable. The heart of power generation lies in the controlled combustion of fuels, be it coal, natural gas, or renewable resources. As the combustion process unfolds, colossal amounts of heat are generated, and without meticulous thermal management, this excess heat can lead to catastrophic consequences.

Then, in the realm of transportation and industrial applications, the significance of thermal management becomes particularly pronounced within combustion engines. These engines, whether propelling automobiles, aircraft, or industrial machinery, rely on controlled combustion processes to harness the energy stored in liquid or gaseous fuels.

Challenges Unique to energy and combustion systems

The intricacies of energy and combustion systems pose unique challenges for thermal management. The extreme temperatures, high-pressure environments, and varying operational conditions demand innovative solutions beyond conventional cooling methods. Addressing these challenges is crucial for unlocking the full potential of energy production and industrial combustion processes.

Revolutionary Heat Processing Products for Enhanced Performance

Advanced Thermal Barriers and Insulation

In the world of energy and combustion, where temperatures can soar to extreme levels, advanced thermal barriers and insulation materials play a pivotal role. Innovations in ceramics, aerogels, and high-temperature-resistant polymers are enhancing the insulation properties, protecting components from heat stress, and ensuring optimal system performance.

Cryogenic Cooling Systems

For applications that operate under extremely low temperatures, such as liquefied natural gas (LNG) facilities, cryogenic cooling systems are emerging as game-changers. These systems leverage the unique properties of cryogenic fluids to efficiently manage heat, ensuring the safe and reliable operation of energy storage and transportation facilities.

Smart Thermal Monitoring and Control Systems

Integrating smart thermal monitoring and control systems is revolutionizing how energy and combustion systems are managed. These systems leverage real-time data and analytics to optimize thermal processes, enhancing efficiency, reducing energy consumption, and minimizing environmental impact.

Innovations in Active Cooling Systems for Combustion Engines:

Advanced Liquid Cooling Systems

In the realm of combustion engines, where precise temperature control is paramount, advanced liquid cooling systems are making significant strides. These systems utilize high-performance coolants and advanced pump technologies to efficiently dissipate heat from critical engine components, improving overall efficiency and reliability.

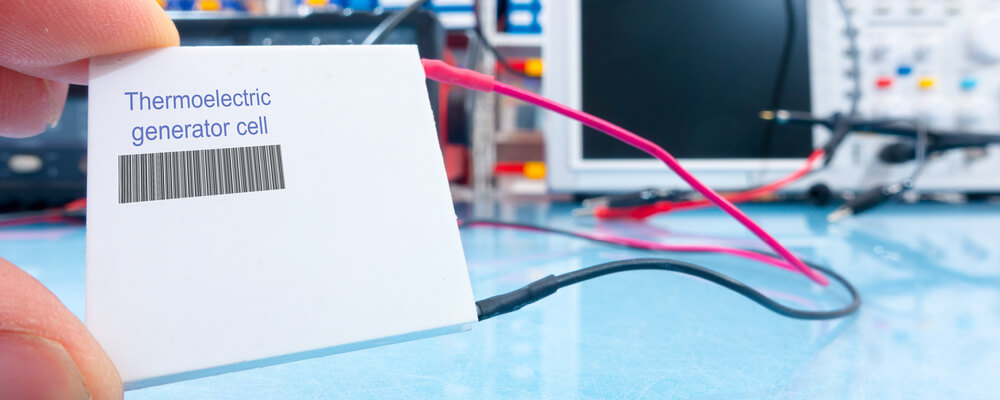

Thermoelectric Generators for Waste Heat Recovery

Energy and combustion systems often generate substantial amounts of waste heat. Thermoelectric generators offer a sustainable solution by converting this waste heat into electrical power. Implementing such systems not only improves overall energy efficiency but also aligns with the growing emphasis on sustainable and eco-friendly practices.

Energy and combustion systems often generate substantial amounts of waste heat. Thermoelectric generators offer a sustainable solution by converting this waste heat into electrical power. Implementing such systems not only improves overall energy efficiency but also aligns with the growing emphasis on sustainable and eco-friendly practices.

Artificial Intelligence in Thermal Management for Enhanced Energy Efficiency

The integration of artificial intelligence is reshaping the landscape of thermal management in energy and combustion systems. AI algorithms can predict and optimize thermal processes, leading to energy savings, reduced emissions, and increased operational efficiency. This intelligent approach is a catalyst for a more sustainable and technologically advanced future.

Navigating the Future: Challenges and Opportunities

As we navigate the path to the future of thermal management in energy and combustion systems, it’s crucial to acknowledge the challenges and opportunities that lie ahead. Balancing the demands for increased efficiency with environmental sustainability will be a key consideration. Moreover, ensuring that these innovations are scalable and adaptable to the diverse array of systems within the industry is imperative for widespread adoption.

Understanding the Future of Thermal Management

In conclusion, the future of thermal management in energy and combustion systems is characterized by a convergence of innovation and necessity. The journey to harnessing heat effectively and sustainably is not only a challenge but an opportunity to revolutionize how we generate and utilize energy. From advanced insulation materials to smart monitoring systems and AI-driven optimization, the possibilities are vast, and the stakes are high. As we stand at the precipice of this thermal revolution, the energy and combustion industry is poised to ignite the future.

Need energy and combustion systems for your company? Contact Lindberg Process Equipment today.