Butterfly valves are a cost-effective and low-maintenance tool that works well within many processing plants. Compared to other valve types, they’re generally a better choice.

Here at Lindberg Process Equipment, we work with various manufacturers to get you the correct valves for your plant. This guide will assist you in learning more about butterfly valves, and how they can benefit the machines at various processing plants.

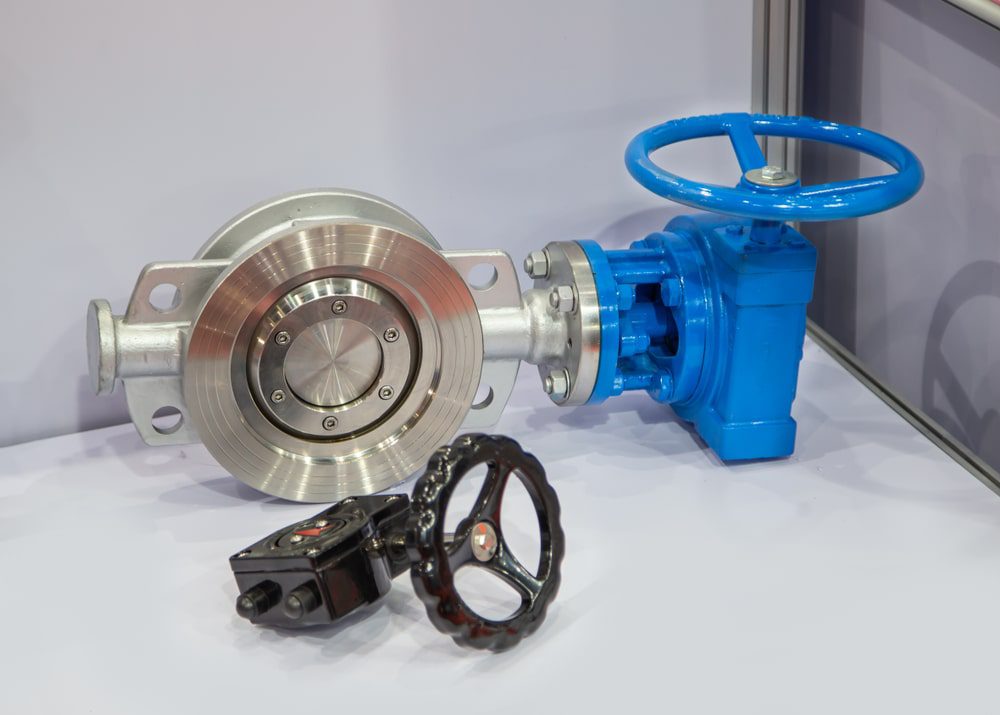

What Is a Butterfly Valve?

Butterfly valves or damper valves are for controlling airflow by turning a disc. The rod of this valve goes through the center of a disc and connects to an actuator. The actuator controls the disc and the movement it makes.

Butterfly valve discs sit perpendicular or parallel to the airflow and always flow. This causes a pressure change for any position the valve is in.

This type of valve gets its name not because it looks like a butterfly, but because of the way it moves. The rod is comparable to a butterfly’s body as the disc moves in the way that the wings would when the butterfly takes flight.

Three Types of Butterfly Valves

There are three different types of butterfly valves to consider. Each one is slightly different, but all serve a similar purpose. Let’s take a look below.

#1. Triple Offset Butterfly Valve

A triple offset butterfly valve is ideal when used in a high-pressure system. Because it can handle up to 1,480 psi of pressure. As the most advanced type of butterfly valve, it’s best to work in various environments and has lower emissions.

This type has two offsets in the center and a third with a right-angled sealing. These are frictionless valves where the components don’t touch until the final point.

#2. High-Performance Double Offset Butterfly Valve

High-performance double offset butterfly valves have an offset in two places. There’s one at the seat of the disc and the bore. This off-center position allows the valve to have more durability for the seal.

It can handle a lot of pressure like a triple offset butterfly valve, but not quite as much. These can handle 1,440 psi of pressure. Cam-action happens from the stem rubbing against the disc during rotation. The cam-action occurs for the first and last ten degrees of the 90-degree rotation.

#3. Zero-Offset Butterfly Valve

Zero-offset butterfly valves have the lowest pressure rating. Only handling up to 250 psi of pressure. These valves are also referred to as rubber seated or concentric valves.

These butterfly valves lack an offset by the valve’s rod and seal by interference with the disc edge at the rod. It is between the rubber seal and the disc.

How Butterfly Valves Work

These types of valves work by regulating the flow of air by stopping, starting, or slowing media. Discs will open and close with a rotation of 90 degrees. Since these valves can handle extreme heat and cold, the seal will keep its integrity. Allowing them to last longer and saving money on replacing them too often. The flow control valve is key to longevity.

What Butterfly Valves are Used For

Butterfly valves control airflow. But because of their high pressure and heat tolerance, they’re better in certain processing plants. These are three of the most popular plants in which you’ll see butterfly valves.

Ship Building

Butterfly valves are corrosion-resistant and, so, can withstand being around saltwater. It’s because of this durability that they’re often used for shipbuilding.

These valves are watertight to keep pipes from leaking and causing issues for passengers on board. Their small size and ability to fit into smaller spaces is another reason they’re ideal for this industry.

Refineries

For refineries, butterfly valves are a popular choice. Most refineries opt for the high-performance valve or triple offset because they’re fire-resistant. These valves can handle a lot of heat, giving you even more reason to choose them for refineries.

Food Processing

Using hygienic valves in food processing plants is critical to keeping consumers safe. Butterfly valves are designed for FDA approval. Making them highly sought after for food processing.

In Closing

Butterfly valves are affordable and low-maintenance to use at almost all processing plants. If you’re looking for butterfly valves to incorporate into your processing plant, Lindberg Process Equipment can assist you in getting the right type. Contact us today to see how we can get you new butterfly valves.