Choosing the right pneumatic valve could make or break your plant’s production. Do you know when to use a 2-way directional valve versus a 3-way directional valve? Is there a better option to increase production? These valves control many aspects of pneumatic systems, so you must know enough to select the right ones for your plant.

What Are Pneumatic Valves?

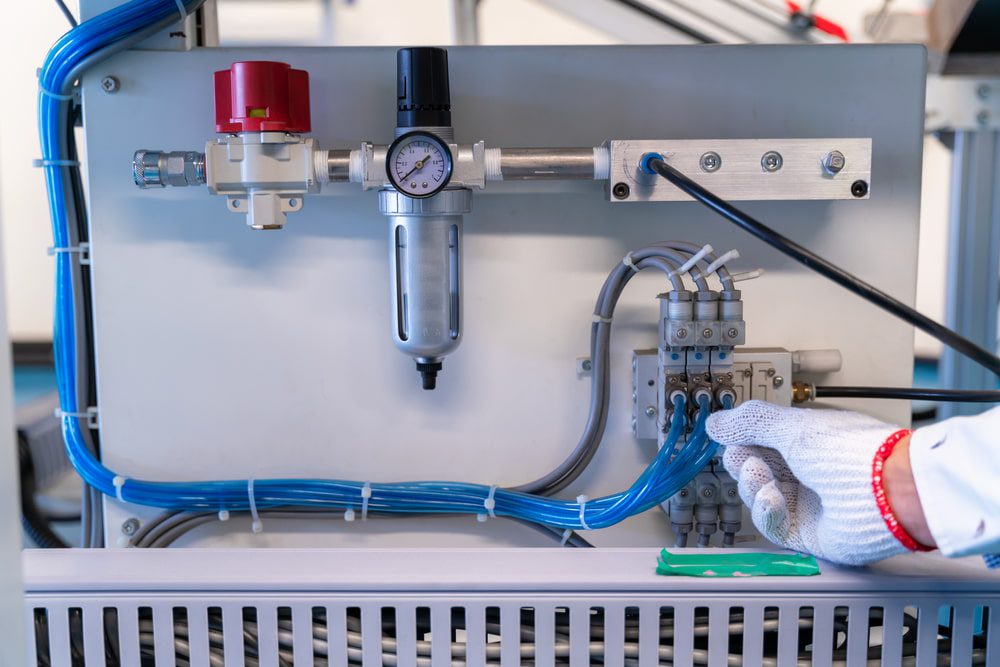

Pneumatic valves manage the flow within a system. These components can assist other valve families in affecting flow and pressure within a pneumatic system. Pneumatic valves can be manually controlled or utilize an electrical coil that reacts to certain conditions and pressure changes to switch direction or stop the flow.

Types of Pneumatic Valves

There are a few types of pneumatic valves but several possible configurations depending on the pneumatic system. For example, the valves you need for a beer brewing system might look different from those used in a car.

Typically, people classify pneumatic valves by their number of entry and exit ports. For example, a 2-way directional valve has two ports and a 3-way directional valve has three ports. Other classifications can include the number of available flow paths or how the device functions.

#1. 2-Way Directional Valves

A 2-way directional valve can turn a device on or off. People often use 2–way directional valves to operate gate valves or ball valves.

Butterfly valves are a type of 2-way directional valve that regulates flow to address different input and output conditions. These 2-way directional valves take up less space and only need a quarter-turn to switch on or off.

When to Use 2-Way Directional Valves

A 2-way directional valve is basically an on-off switch that’s easy to operate. The primary purpose is to start or stop flow through the system. You use 2-way directional valves every day, even at home. The faucets in your house feature 2-way directional valves to control water flow.

#2. 3-Way Directional Valves

3-way directional valves have three ports with unique purposes. A 3-way directional valve features one port that connects to another device and one that hooks to a source of airflow. The third port on a 3-way directional valve serves as a vent when the system needs to relieve pressure or exhaust.

How to Use 3-Way Directional Valves

A 3-way directional valve allows you to release pressure or create a vacuum effect. Since it features an extra port that serves as a vent, it is easy to create suction and release pressure at any point. 3-way directional valves work best when you need to maintain constant flow but want to shift between supply and return.

#3. 4-Way Directional Valves

Many pneumatic systems use 4-way directional valves more often than 2-way or 3-way directional valves. These devices feature four ports: two that connect to actuators, one for venting, and one for airflow. Consequently, they can simultaneously pressurize and vent two ports.

#4. 5-Way Directional Valves

A 5-way directional valve is less common but serves a purpose for air circuits. It functions much like a 4-way directional valve but with an extra port that can attach to another tank or serve as a second vent.

How Do Pneumatic Valves Work?

Pneumatic valves are usually manually operated or controlled by a mechanism. Manually controlled pneumatic valves rely on humans to operate. Alternatively, an electrical component can trigger the valve to change positions, like a solenoid valve that relies on magnetic fields.

Pneumatic valves are usually manually operated or controlled by a mechanism. Manually controlled pneumatic valves rely on humans to operate. Alternatively, an electrical component can trigger the valve to change positions, like a solenoid valve that relies on magnetic fields.

Each type of valve has its own purpose within the system. While a 2-way directional valve seems simplistic, a dysfunctional one can throw off the entire flow. A 3-way directional valve is more complex, but it might not improve the function in all situations.

Additional Considerations for Pneumatic Valves

Knowing the difference between a 2-way directional valve and a 3-way directional valve is more than enough pneumatic valve knowledge for most people. However, learning how to configure a system with a series of 2-way and 3-way directional valves is more challenging and best left to the professionals.

There are multiple configurations depending on the type of valve you use, and you can even use a shut-off valve in many cases. It’s a good idea to speak with your team and work with a knowledgeable supplier who can deliver the quality products you need to keep production moving.

Contact Lindberg Process Equipment About Your Pneumatic Valve Needs Today!

When you work with Lindberg Process Equipment, you can expect the highest level of customer service and quality devices. Contact us today to learn more about our products and how we can meet your pneumatic valve needs.